New assembly and connection technology for reliable, bendable electronics

Project duration: 01.04.2022 until 31.03.2025

Project description

The HyPerStripes project is developing new technologies for the cost-effective production and assembly of long, intelligent and flexible PCBs to replace conventional electrical cables and connection technologies. To this end, some project partners are developing roll-to-roll processes for flexible and stretchable PCBs, which will largely eliminate the current dimensional limitations. There is a particular need for such PCBs in the medical sector, as their use leads to miniaturization and thus also to the use of more sensors and other electrical components, which can significantly improve diagnostics and therapies. Conventional medical products currently mainly use wires or strands, which are very time-consuming to assemble manually, resulting in up to 80% of the total product costs and also taking up a lot of space. In the project, OSYPKA is developing a neuroimplant whose extremities are connected with long, flexible and stretchable PCBs. The distal end of the implant, which has a large number of electrodes, is also equipped with an application-specific integrated circuit (ASIC), which is used to digitize the measurement signals. The ASIC is connected via a novel, biocompatible connection technology (Nano Wiring), which is being developed by a project partner and will be verified in the project.

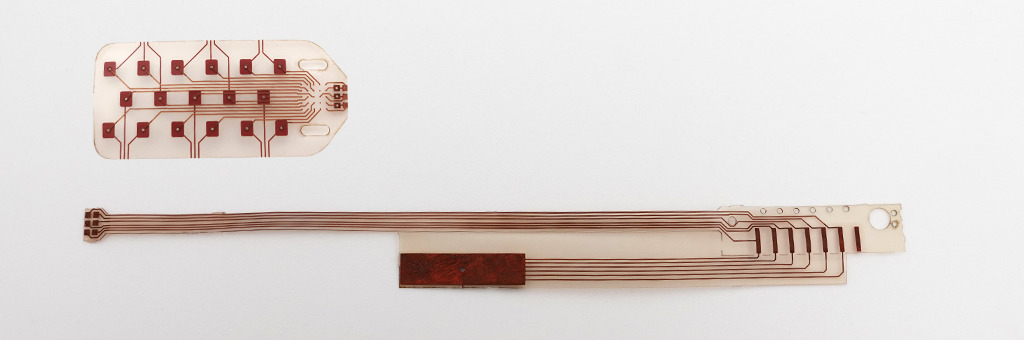

Demonstrator

The picture shows a draft of the implant demonstrator. The demonstrator can be roughly divided into three areas. The electrode patch with integrated ASIC, which is to be used to measure and stimulate neuronal systems, the flexible and stretchable PCB (or the HyPerStripe), which transmits the electrical signals to the proximal connection, and the connector, which establishes the connection to the implantable pulse generator (IPG).